Rental | Sale | Contracting

Let's Partner Up!

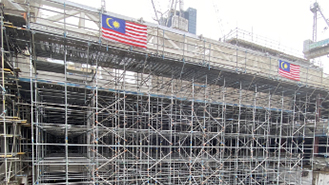

Dscaff believes that we are stronger when we work together. We can support you with a supply of scaffolding for your new build and maintenance projects.

Key Advantages When You Rent Scaffolding From Us:

- Save expensive capex and financing costs

-

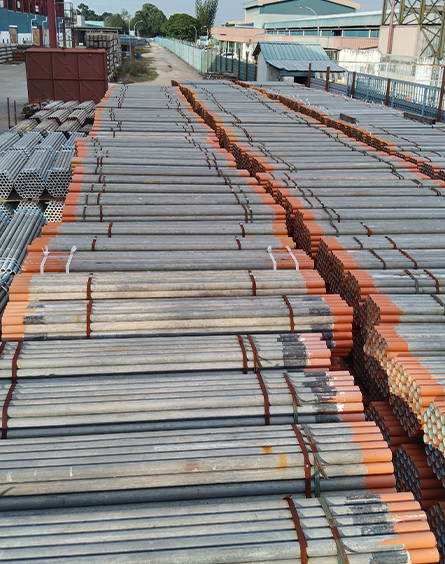

Increase your capability to secure bigger projects using our huge stock of scaffolding

- Return materials after use; you can save on Storage & Security costs

- We can provide you with Technical and Marketing Support Services

-

Our Scaffolding Materials comply with Malaysian and International Standards

Integrated Management System Certification

Integrated Management System Certification

ISO 9001:2015,

ISO 14001:2015,

ISO 45001:2018,

ISO 29001:2020

International Standard

Our Partners

Capital Partners

Auditor

Product Partners

International Standard

Our Partners

Capital Partners

Auditor

Product Partners